Diamond Cutters

SUPER PREMIUM

EXCEL PLUS SEGMENTED SAW

Product Features

- 100% hot press

- Anti clog bond system

- Long life

- High premium treated diamonds

- Effortless fast cutting

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Segmenter | 105 | 1.8 X 8 | 20 | Super Hard Granite and Stones |

EXCEL PLUS CONTINUOUS RIM

Product Features

- 100% hot press

- Anti clog bond system

- Long life

- High premium treated diamonds

- Effortless fast cutting

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Rim | 110 | 2 x 10 | 20 | Super Hard Granite and Stones |

Product Features

- 100% advanced hot press

- 1000 RFT record output.

- Fine finish

- 15 mm jumbo segment

- Ultra smooth cutting

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Segmented | 110 | 1.7 x 1.5 | 20 | Super Hard Granite and Stones |

SPEED LONG LIFE

Product Features

- 100% hot press

- Anti wear bond system

- Long life – 3 times of normal saws.

- Special coated diamond grains

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Segmented | 110 | 1.8 x 10 | 20 | Abrasives Material and Medium Hard Stones |

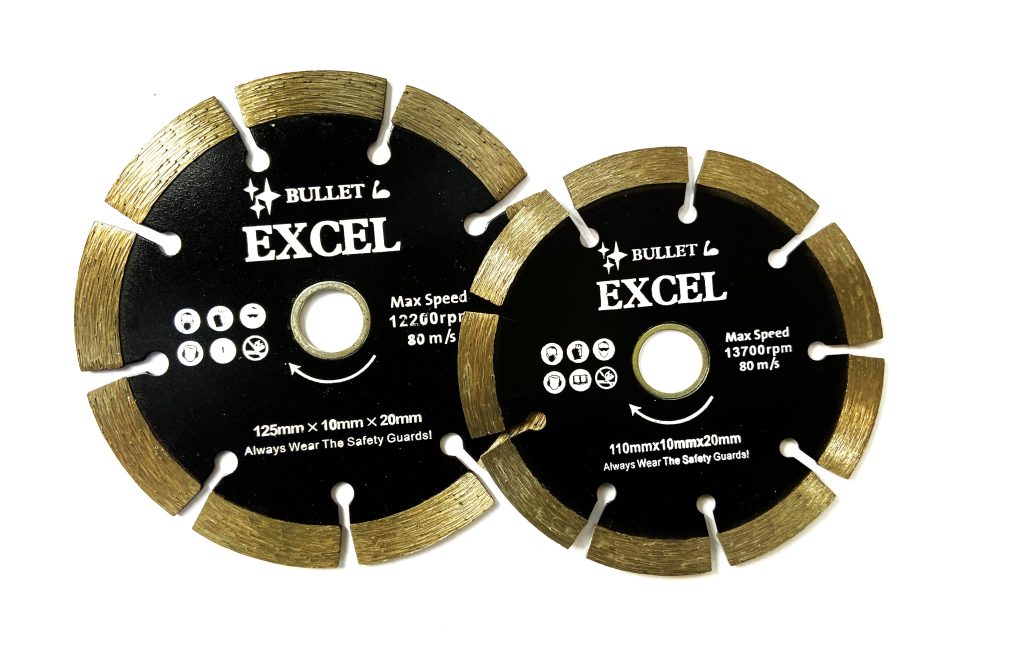

PREMIUM

Bullet

Product Features

- Unique turbo design

- Fast cutting bond

- Premium diamond grits

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Turbo | 105 | 1.8 X 8 | 20 | Granite and Concrete |

| Turbo | 110 | 1.8 X 10 | 20 | Granite and Concrete |

| Turbo | 125 | 2.0 x 10 | 22.23 | Granite and Concrete |

| Turbo | 150 | 2.0 x 10 | 22.23 | Granite and Concrete |

| Turbo | 200 | 2.0 x 10 | 22.23 | Granite and Concrete |

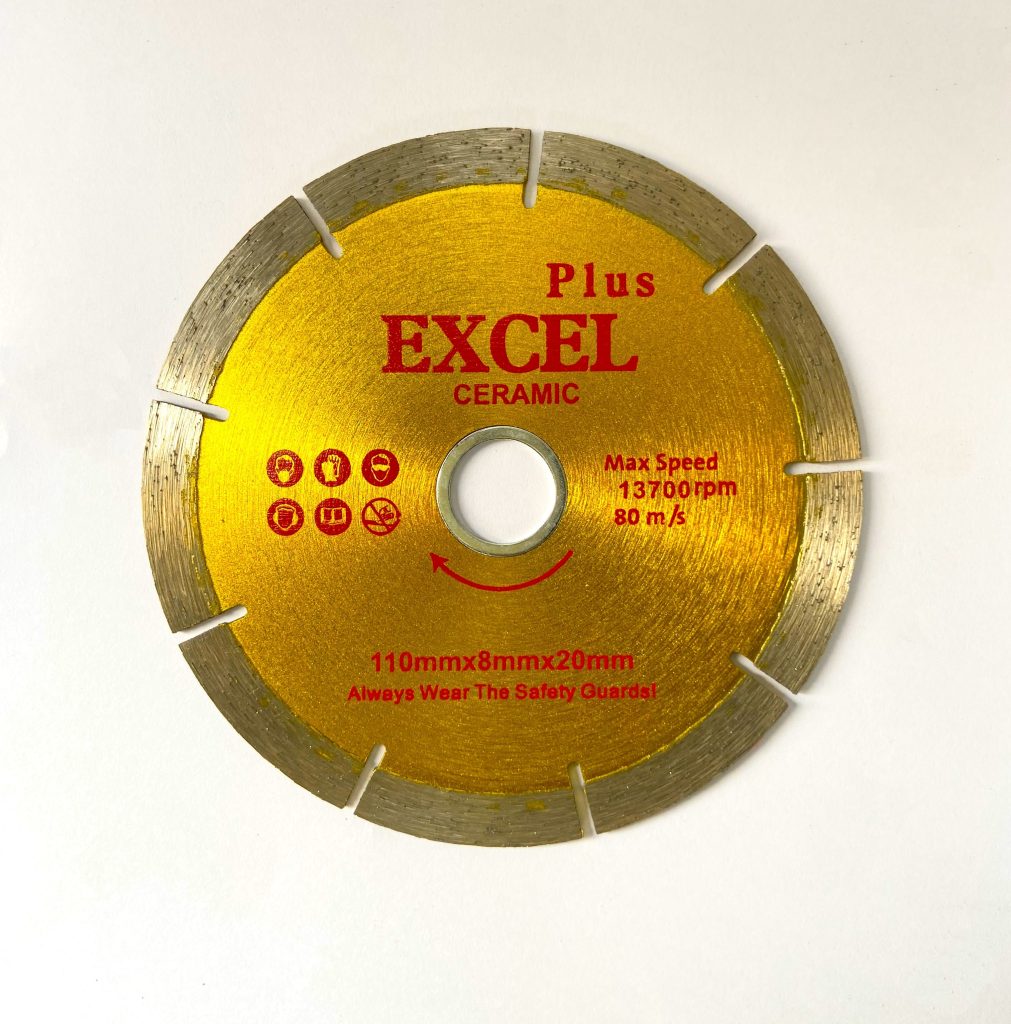

CERAMIC SAWS

SPEED GLASS CUTTING SAW

Product Features

- Ultra thin body – 0.9 mm thick

- Laser cutting quality

- High quality premium diamond coating

- Suitable for glass, ceramic and POP

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Electro plated | 100 | 0.8 x 20 | 20 | Glass,Ceramic and POPs |

EDGE CUTTING SAWS

EXCEL PLUS DIAMOND SAW

Product Features

- Treated diamond grits

- Soft cutting for hard granites

- Chip free edges

- Longest life

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Segmented | 355 | 3.2x9 | 50 | Hard Granite |

PREMIUM CARVING SAWS

SPEED CUP WHEELS

Product Features

- Larger diamond grits

- Ultra fast grinding

- Vibration free balanced body

- Longest life

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Segmented | 75 | 2.5 | 20 | Granite |

| Segmented | 100 | 2.5 | 20 | Granite |

WOOD CUTTER SAWS

EXCEL GOLD

Product Features

- High density alloy treated tungsten carbide tips

- CNC profiled cutting edges

- Fast cutting and Superior finish

- Longer life

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| TCT | 110 | 1.8 X 40T | 20 | Hard Wood and Hot Press Plywood |

| TCT | 110 | 1.8 X 30T | 20 | Hard Wood and Hot Press Plywood |

| TCT | 125 | 1.8 X 40T | 20 | Hard Wood and Hot Press Plywood |

| TCT | 125 | 1.8 X 30T | 20 | Hard Wood and Hot Press Plywood |

SPEED DIAMOND SAW

Product Features

- Premium diamond grits

- Fast cutting

- Chip free Finish

- Long life

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Segmented | 355 | 3.2x9 | 50 | Granite |

SPEED DIAMOND MULTI PURPOSE SAW

Product Features

- Cuts Metal, Stone, Concrete, Fibre Glass etc.

- Unique Vacuum brazing

- Faster Cutting and Longer life

| Dimension ( mm ) | ||||

|---|---|---|---|---|

| Type | Dia ( D ) | THK ( T ) x Segment Height ( H ) | Bore | Use on |

| Vacuum Brazed | 350 | 2.8x3 | 25.4 | Metal, Stone, Concrete Fibre and Others |

Precision in Stone: The Art of Diamond Cutters

Diamond cutters, the skilled artisans of the gemstone world, bring to life the brilliance and beauty locked within these precious stones. The process of cutting diamonds is a delicate art that requires both precision and expertise. Each facet must be meticulously crafted to enhance the stone’s natural attributes, allowing light to dance and refract, creating a dazzling display.

These artisans navigate the intricacies of the diamond’s structure, employing various cutting styles like the brilliant cut or princess cut to achieve the desired aesthetic. The result is not just a piece of jewelry but a masterpiece that captures the essence of elegance and sophistication.

Unveiling the Secrets: Techniques Employed by Diamond Cutters

Behind the scenes, diamond cutters employ a combination of age-old techniques and cutting-edge technology to shape these precious gems. Traditional methods involve cleaving, sawing, and bruting, each step demanding a delicate touch to avoid damaging the stone. Modern technologies like laser cutting have revolutionized the industry, allowing for unprecedented precision and customization. Diamond cutters leverage their expertise to strike a balance between maximizing carat weight and optimizing the stone’s brilliance.

It’s a delicate dance between tradition and innovation, resulting in diamonds that are not just valuable but also uniquely crafted works of art.

Crafting Dreams: The Impact of Diamond Cutters on Jewellery Design

Diamond cutters play a pivotal role in shaping the dreams of those who wear their creations. Their skillful hands turn rough diamonds into sparkling centerpieces for engagement rings, necklaces, and earrings. The choice of cut can significantly influence the overall design, from classic round brilliants to avant-garde shapes that push the boundaries of creativity. Diamond cutters collaborate closely with Jewellery designers to bring visions to life, considering factors such as symmetry, proportion, and polish.

In this collaborative dance between cutters and designers, diamonds become not only symbols of love and luxury but also embodiments of artistry and craftsmanship that stand the test of time.