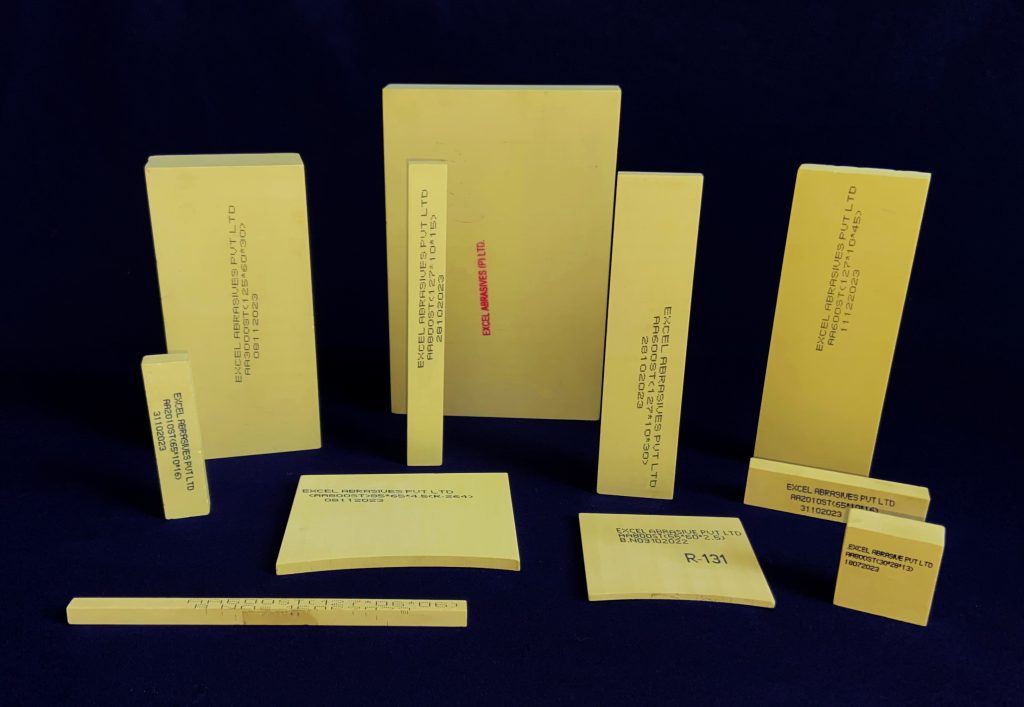

Finish & Super Finish Stones

ALUMINUM OXIDE

Vitrified Aluminum Oxide is a mined mineral. It is processed to grit sizes 6 to 1200. oxide crystal have sharp-edged black shapes. The cutting surface is constantly renewed keeping it sharp and free of build up.

ALUMINUM OXIDE SPECIFICATIONS CHART

| GRAIN TYPES | GRIT SIZES | GRIT SIZES | STONE HARDNESSES | STONE SIZES | STONE LENGTHS | MOUNTING |

|---|---|---|---|---|---|---|

| Aluminum Oxide | 80 | 600 | H ( ultra soft ) | 1/4 " x 1/4 " | 1 " -4 " | Mounded |

| Aluminum Oxide white | 120 | 800 | 1 ( soft ) | 5/16 " x 5/16 " | 1 " -6 " | Unmounted |

| Ceramic Oxide | 150 | 1000 | IP ( induced parasity ) | 3/8 " x 3/8 " | 1 " -8 " | |

| Resin Bond | 180 | 1200 | J ( soft medium ) | 1/2 " x 1/2 " | 1 " -8 " | |

| 220 | 1500 | K ( medium ) | 5/8 " x 5/8 " | 1 " -8 " | ||

| 320 | 2000 | L ( medium hard ) | 3/4 " x 3/4 " | 1 " -8 " | ||

| 400 | M ( hard ) | 1 " x 1 " | 1 " -8 " |

SILICON CARBIDE

Vitrified Silicon is a mined mineral it is harder and more Friable than aluminum oxide silicon carbide has sharp structure and is often used for hard, nonferrous materials and extra fine finishes.

ALUMINUM OXIDE SPECIFICATIONS CHART

| GRAIN TYPES | GRIT SIZES | GRIT SIZES | STONE HARDNESSES | STONE SIZES | STONE LENGTHS | MOUNTING |

|---|---|---|---|---|---|---|

| Silicon Carbide Green | 80 | 600 | H ( ultra soft ) | 1/4 " x 1/4 " | 1 " -4 " | Mounded |

| Silicon Carbide Black | 120 | 800 | 1 ( soft ) | 5/16 " x 5/16 " | 1 " -6 " | Unmounted |

| 150 | 1000 | IP ( induced parasity ) | 3/8 " x 3/8 " | 1 " -8 " | ||

| 180 | 1200 | J ( soft medium ) | 1/2 " x 7/16 " | 1 " -8 " | ||

| 220 | 1500 | K ( medium ) | 1/2 " x 1/2 " | 1 " -8 " | ||

| 320 | 2000 | L ( medium hard ) | .375 " x .375 " | 1 " -8 " | ||

| 400 | M ( hard ) | 5/8 " x 5/8 " | 1 " -8 " |

The Art of Surface Perfection: Understanding Finish & Super Finish Stones

Achieving a flawless surface finish is an art that demands precision and the right tools. In the realm of metalworking, Finish & Super Finish Stones emerge as indispensable instruments for the attainment of impeccable surfaces. The Finish Stones play a pivotal role in refining surfaces, eliminating imperfections, and enhancing the overall aesthetic appeal of materials. Whether it’s smoothing out rough edges, polishing intricate details, or fine-tuning critical components, these stones stand as silent artisans in the pursuit of perfection.

They cater to a diverse range of industries, including manufacturing, automotive, and aerospace, where the quality of surface finish is paramount.

Unveiling the Mastery of Super Finish Stones: Elevating Precision to Unprecedented Heights

Super Finish Stones, an advanced iteration in the world of abrasive tools, take the pursuit of perfection to unprecedented heights. With an exceptional ability to deliver ultra-fine surface finishes, these stones are engineered for the most delicate and demanding applications. Their micro-abrasive nature allows craftsmen to achieve mirror-like surfaces with sub-micron precision. From intricate moulds in the precision machining industry to critical components in the medical field, Super Finish Stones excel in tasks where the margin for error is almost non-existent.

The mastery of these stones lies not just in their abrasive prowess but in the meticulous craftsmanship they enable, setting a new standard for surface refinement.

The Role of Finish & Super Finish Stones in Industrial Excellence

In the industrial landscape, where efficiency and quality reign supreme, Finish & Super Finish Stones carve a niche as indispensable tools for achieving excellence. Industries ranging from aerospace to medical devices rely on these stones to impart the desired surface finish to components and products. The Finish Stones, with their versatility, cater to a broad spectrum of materials, while Super Finish Stones, with their precision, are instrumental in applications demanding perfection at a microscopic level.

As manufacturers continue to push the boundaries of what’s achievable, these stones remain steadfast companions in the journey towards unparalleled industrial excellence, ensuring that every finished product tells a story of precision, care, and uncompromised quality.