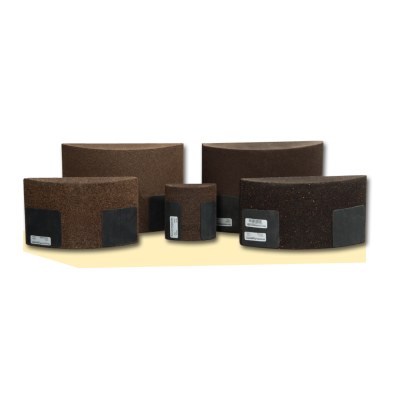

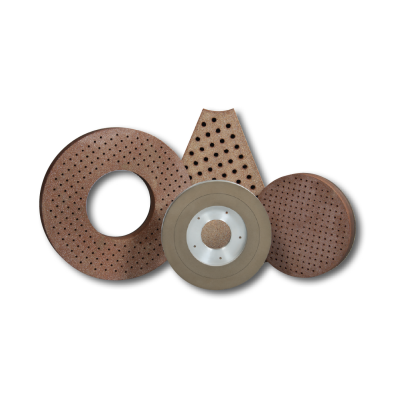

SEGMENT ABRASIVES

Heading

Excel Abrasive manufactures an extensive variety of abrasive segments for most surface grinders and we offer one of the widest range of segment of shapes, styles and sizes in both metric and English dimensions. They include all of the common Blanchard grinding shapes, knife grinder shapes and shapes to fit most of the less common European grinding machines.

Excel Abrasives provides segments to grind machine knives and chipper blades, steel plate, aluminum and aircraft alloys, tool steels and low carbon steels, cast iron and for many other applications. Our proprietary ceramic grain segments are specifically designed to ‘hog off’ material and offer exceptional value for grinding steel plate on large, high horsepower machines.

Design & Engineering Services

All Excel Abrasives products are custom designed to meet specific customer requirements. Through a thorough understanding of all of the parameters, we will develop a formulation to meet the unique characteristics of each application. Our outside sales staff and our inside application engineers combine their knowledge of abrasives and grinding to optimize a product that will produce the desired results.

Our abrasive engineers have a wealth of grinding application knowledge and experience. They are eager to help resolve any specific grinding questions that you may have, whether they are wheel, setup or machine related.

Grains

A variety of abrasive grains are used to produce industrial grinding wheels. Most commonly used are various forms of aluminum oxide and silicon carbide.

There are several types of aluminum oxide used by Excel Abrasives. These grains are used in a range of grit sizes which are given a numerical designation. The smaller the number, the larger the grit size. Coarser grits are typically used to remove large amounts of stock and on relatively soft materials. Finer grits are used to produce smooth finishes with little stock removal and on harder materials. These materials may be used singularly or in combination with each other, depending on a wide variety of factors

| Shape | Product | Approx. Weight Lbs. | Width Inch/MM | Height Inch/MM | Length Inch/MM | Area Inch 2 | |||

| BL18 | 5.6 | 7 1/16 | 1 3/4 | 6 | 11.8 | ||||

| BL20 | 5.6 | 5 11/16 | 2 | 6 | 10.6 | ||||

| BL42 | 19.3 | 10 1/8 | 3 | 8 | 29 | ||||

| CD18 | 9.0 | 11 1/4 | 2 1/4 | 6 | 18.4 | ||||

| CD18-8 | 11.1 | 11 1/4 | 2 1/4 | 8 | 18.4 | ||||

| CD18XT8 | 19.0 | 11 1/4 | 3 | 8 | 27.125 | ||||

| CD20 | 5.0 | 8 | 1 7/8 | 6 | 12.8 | ||||

| CD8 | 9.0 | 4 3/4 | 1 1/4 | 4 | |||||

| CH8 | 3.4 | 4 1/16 / 3 5/16 | 1 1/2 | 8 | 5.3 | ||||

| CP14 | 2.6 | 5 5/16 | 1 1/2 | 5 | |||||

| EL450 | 2.7 | 125 / 85 | 35 | 150 | |||||

| GOCKELG3 | 1.3 | 95/72 | 25 | 120 | |||||

| GOCKELG 100 | 5.9 | 120/106 | 41 | 250 | 7.174 | ||||

| HARA2 | 3.6 | 4.19 | 2 | 5 1/2 | |||||

| HM18 | 2.9 | 5 | 1 1/2 | 6 | 7 | ||||

| LUMSDEN12 | 14.3 | 6 5/8 / 4 1/2 | 2 1/4 | 12 | |||||

| NO18 | 3.4 | 5 | 1 1/2 | 6 | 6.75 | ||||

| NO18-8 | 3.6 | 5 | 1 1/2 | 8 | |||||

| NO18A | 5.2 | 5 9/16 | 2 1/4 | 6 | 11.4125 | ||||

| REFORM300 | 1.1 | 60 | 25 | 150 | 2.325 | ||||

| REFORM350 | 1.4 | 80 | 25 | 150 | 3 | ||||

| REFORM500 | 3.5 | 90 | 35 | 200 | 4.8825 | ||||

| REFORM600 | 4.0 | 110 | 40 | 200 | 6.82 | ||||

| REFORM600M | 3.6 | 110 | 40 | 160 | 6.82 | ||||

| S31 | 1.1 | 64/70 | 25 | 150 | 2.58 | ||||

| S32 | 3.3 | 94/103 | 38 | 180 | 5.778 | ||||

| S33 | 0.6 | 60/54 | 22 | 110 | 1.94 | ||||

| STG12 | 2.8 | 5 5/16 | 1 1/4 | 5 | 7.2 | ||||

| STG14 | 2.5 | 5 5/16 | 1 1/4 | 4 | 6.3 | ||||

| STG16A | 3.6 | 6 | 1 1/4 | 5 | 7.2 | ||||

| STG18 | 4.8 | 6 13/16 | 1 1/2 | 5 | 9.7125 | ||||